High-end application of nano-zirconia: additive for lithium battery materials

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-01-06

- Views:0

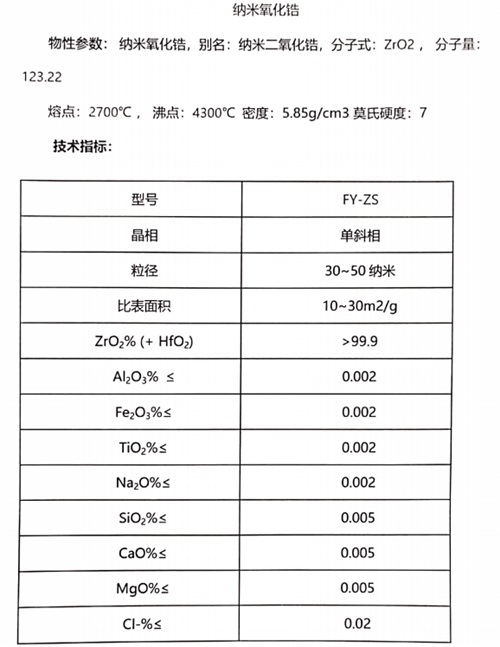

(Summary description)ZrO2, white powder, density between 5.68-6.27g/cm3, melting point is 2715 ℃, one of the important ceramic materials. It has the advantages of low thermal conductivity, high temperature resistance, corrosion resistance, stable chemical properties, etc., and its crystal phase can be stabilized after doping. Pure ZrO2 has three different crystal forms at room temperature. Due to the asymmetry of the crystal structure, the monoclinic phase is not suitable as an electrolyte material, while the cubic fluorite structure of the high temperature phase has a large number of octahedral voids, which are conducive to the transport of oxygen ions. , so it has a higher conductivity. In addition, it is a relatively abundant substance in nature.

High-end application of nano-zirconia: additive for lithium battery materials

(Summary description)ZrO2, white powder, density between 5.68-6.27g/cm3, melting point is 2715 ℃, one of the important ceramic materials. It has the advantages of low thermal conductivity, high temperature resistance, corrosion resistance, stable chemical properties, etc., and its crystal phase can be stabilized after doping. Pure ZrO2 has three different crystal forms at room temperature. Due to the asymmetry of the crystal structure, the monoclinic phase is not suitable as an electrolyte material, while the cubic fluorite structure of the high temperature phase has a large number of octahedral voids, which are conducive to the transport of oxygen ions. , so it has a higher conductivity. In addition, it is a relatively abundant substance in nature.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-01-06

- Views:0

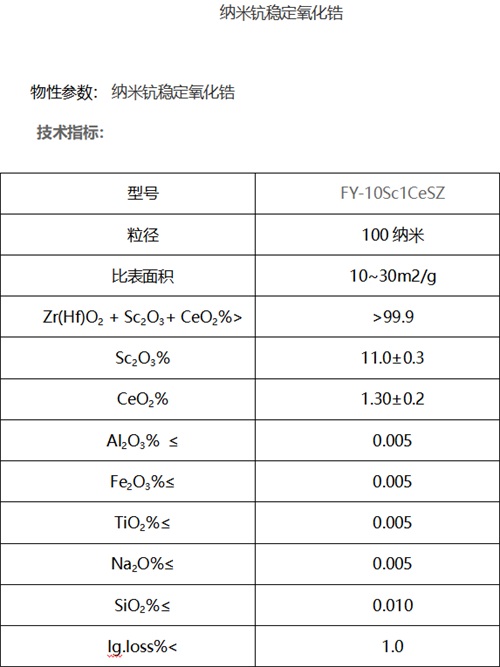

(2) Nano Scandium Stabilized Zirconia

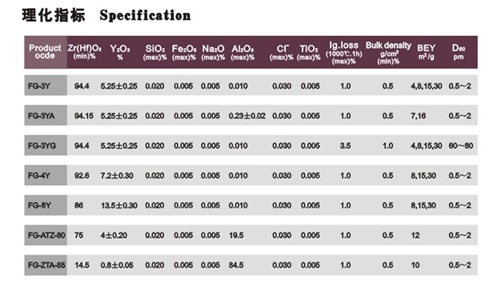

(3) Yttrium stabilized zirconium powder

Scan the QR code to read on your phone

Relevant information

Product Recommendation

Consultation Service

We are willing to cooperate wholeheartedly with people from all walks of life, and welcome new and old friends to visit our company to guide our work. All the staff of Fengye Zirconium warmly welcome friends from all walks of life to visit us and create great achievements together!

ChaoZhou Fengye Zirconium New Materials Co.,Ltd.

Domestic Sales Department:

Tel:+86 -768-6730239

Fax:+86 -768-6732199

Contact: Cheng Danxuan

E-Mail:donna@fysy.cn

QQ:925753031

QQ:2873666207

WeChat:fengyegaoye

Website

COPYRIGHT © ChaoZhou Fengye Zirconium New Materials Co.,Ltd. All Rights Reserved 粤ICP备11078101号 Power by: www.300.cn