Fengye Zirconium Industry Feature: Such zirconia products can seize the SOFC industry outlet

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-01-06

- Views:0

(Summary description)Since the second half of this year, the prices of main zirconium chemical materials such as zirconium oxychloride and zirconium oxide have continued to jump. Mr. Luo Shunfeng, executive director of Jiexin Resources (Hong Kong) Co., Ltd., analyzed this (original post address: Why did zirconium-based chemicals skyrocket, and how long will it last? The most reliable answer is here!), although the fuse is zirconium The supply of British sand, especially standard sand, is insufficient, but in fact there is also the impact of new market demand - solid oxide fuel cells (SOFC) are one of the key points.

Chaozhou is one of the birthplaces of Chinese ceramic culture. The ceramic industry is fully developed. Chaozhou Fengye Zirconium New Material Co., Ltd. (hereinafter referred to as Fengye Zirconium), as a high-tech enterprise specializing in the research and development and production of zirconia series products, has many intelligent The functional production workshop and R&D experiment center are large-scale manufacturers in China that can independently complete all production processes from powder production, molding, sintering to fine processing, especially in the preparation of high-purity submicron and nano-scale zirconia powders. It has successfully become one of the few zirconia material suppliers that can meet the needs of the solid oxide fuel cell (SOFC) industry.

Fengye Zirconium Industry Feature: Such zirconia products can seize the SOFC industry outlet

(Summary description)Since the second half of this year, the prices of main zirconium chemical materials such as zirconium oxychloride and zirconium oxide have continued to jump. Mr. Luo Shunfeng, executive director of Jiexin Resources (Hong Kong) Co., Ltd., analyzed this (original post address: Why did zirconium-based chemicals skyrocket, and how long will it last? The most reliable answer is here!), although the fuse is zirconium The supply of British sand, especially standard sand, is insufficient, but in fact there is also the impact of new market demand - solid oxide fuel cells (SOFC) are one of the key points.

Chaozhou is one of the birthplaces of Chinese ceramic culture. The ceramic industry is fully developed. Chaozhou Fengye Zirconium New Material Co., Ltd. (hereinafter referred to as Fengye Zirconium), as a high-tech enterprise specializing in the research and development and production of zirconia series products, has many intelligent The functional production workshop and R&D experiment center are large-scale manufacturers in China that can independently complete all production processes from powder production, molding, sintering to fine processing, especially in the preparation of high-purity submicron and nano-scale zirconia powders. It has successfully become one of the few zirconia material suppliers that can meet the needs of the solid oxide fuel cell (SOFC) industry.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2022-01-06

- Views:0

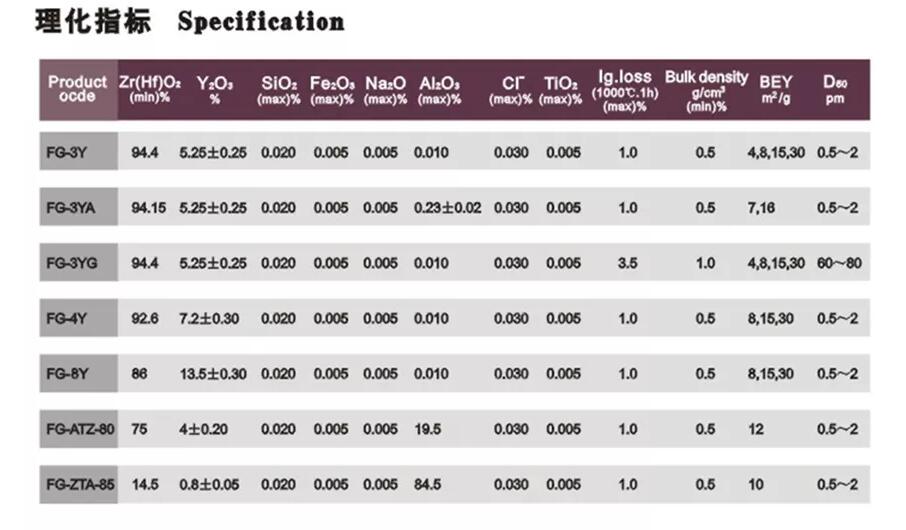

Fengye Zirconium's yttrium-stabilized zirconia powder production capacity reaches 3,600 tons/year

In the ceramic industry, I heard the theory that "good flour can make good steamed buns" more than once, but it is not easy to really agree and implement it. The zirconia powder of Fengye Zirconium is prepared by chemical co-precipitation and hydrolysis. Although the process is complicated and the cost is high, it is better than the powder agglomeration, narrow particle size distribution, high purity, and good phase structure.

Physical and chemical indexes of yttrium stabilized zirconia powder

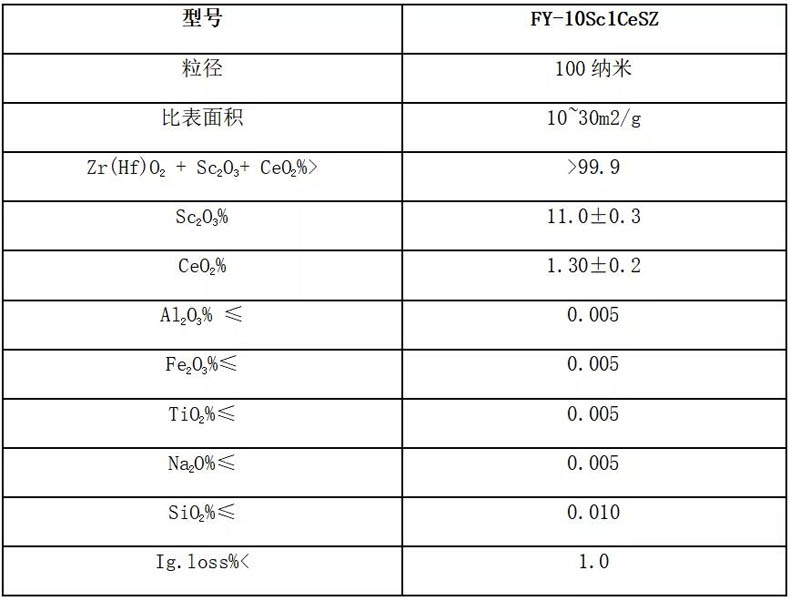

Nanometer Scandium Stabilized Zirconia Specifications

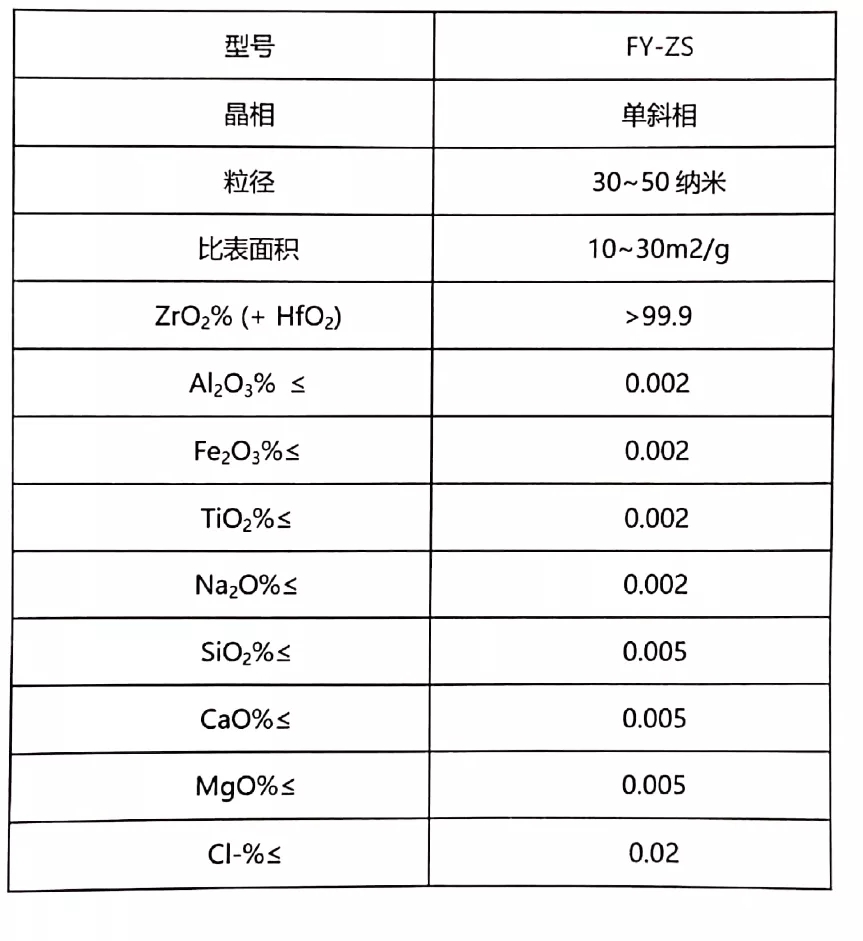

Nano zirconia technical indicators

Scan the QR code to read on your phone

Relevant information

Product Recommendation

Consultation Service

We are willing to cooperate wholeheartedly with people from all walks of life, and welcome new and old friends to visit our company to guide our work. All the staff of Fengye Zirconium warmly welcome friends from all walks of life to visit us and create great achievements together!

ChaoZhou Fengye Zirconium New Materials Co.,Ltd.

Domestic Sales Department:

Tel:+86 -768-6730239

Fax:+86 -768-6732199

Contact: Cheng Danxuan

E-Mail:donna@fysy.cn

QQ:925753031

QQ:2873666207

WeChat:fengyegaoye

Website

COPYRIGHT © ChaoZhou Fengye Zirconium New Materials Co.,Ltd. All Rights Reserved 粤ICP备11078101号 Power by: www.300.cn